[version 13][version 12][version 11][version 10][version 9][version 8][version 7][version 6]

2.3 Breaking of a dam

In this tutorial we shall solve a problem of a

simplified dam break in 2 dimensions using the interFoam solver. The feature of the

problem is a transient flow of two fluids separated by a sharp

interface, or free surface. The two-phase

algorithm in interFoam is based

on the volume of fluid (VOF) method in which a phase transport

equation is used to determine the relative volume fraction of the

two phases, or phase fraction  , in each computational

cell. Physical properties are calculated as weighted averages based

on this fraction. The nature of the VOF method means that an

interface between the phases is not explicitly computed, but rather

emerges as a property of the phase fraction field. Since the phase

fraction can have any value between 0 and 1, the interface is never

sharply defined, but occupies a volume around the region where a

sharp interface should exist.

, in each computational

cell. Physical properties are calculated as weighted averages based

on this fraction. The nature of the VOF method means that an

interface between the phases is not explicitly computed, but rather

emerges as a property of the phase fraction field. Since the phase

fraction can have any value between 0 and 1, the interface is never

sharply defined, but occupies a volume around the region where a

sharp interface should exist.

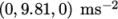

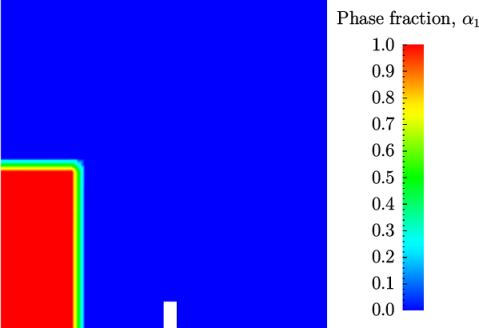

The test setup consists of a column of water at

rest located behind a membrane on the left side of a tank. At time

,

the membrane is removed and the column of water collapses. During

the collapse, the water impacts an obstacle at the bottom of the

tank and creates a complicated flow structure, including several

captured pockets of air. The geometry and the initial setup is

shown in Figure 2.21

.

,

the membrane is removed and the column of water collapses. During

the collapse, the water impacts an obstacle at the bottom of the

tank and creates a complicated flow structure, including several

captured pockets of air. The geometry and the initial setup is

shown in Figure 2.21

.

2.3.1 Mesh generation

The user should go to their run directory and copy the damBreak case from the $FOAM_TUTORIALS/multiphase/interFoam/laminar/damBreak directory, i.e.

run

cp -r $FOAM_TUTORIALS/multiphase/interFoam/laminar/damBreak/damBreak .

17

18vertices

19(

20 (0 0 0)

21 (2 0 0)

22 (2.16438 0 0)

23 (4 0 0)

24 (0 0.32876 0)

25 (2 0.32876 0)

26 (2.16438 0.32876 0)

27 (4 0.32876 0)

28 (0 4 0)

29 (2 4 0)

30 (2.16438 4 0)

31 (4 4 0)

32 (0 0 0.1)

33 (2 0 0.1)

34 (2.16438 0 0.1)

35 (4 0 0.1)

36 (0 0.32876 0.1)

37 (2 0.32876 0.1)

38 (2.16438 0.32876 0.1)

39 (4 0.32876 0.1)

40 (0 4 0.1)

41 (2 4 0.1)

42 (2.16438 4 0.1)

43 (4 4 0.1)

44);

45

46blocks

47(

48 hex (0 1 5 4 12 13 17 16) (23 8 1) simpleGrading (1 1 1)

49 hex (2 3 7 6 14 15 19 18) (19 8 1) simpleGrading (1 1 1)

50 hex (4 5 9 8 16 17 21 20) (23 42 1) simpleGrading (1 1 1)

51 hex (5 6 10 9 17 18 22 21) (4 42 1) simpleGrading (1 1 1)

52 hex (6 7 11 10 18 19 23 22) (19 42 1) simpleGrading (1 1 1)

53);

54

55defaultPatch

56{

57 type empty;

58}

59

60boundary

61(

62 leftWall

63 {

64 type wall;

65 faces

66 (

67 (0 12 16 4)

68 (4 16 20 8)

69 );

70 }

71 rightWall

72 {

73 type wall;

74 faces

75 (

76 (7 19 15 3)

77 (11 23 19 7)

78 );

79 }

80 lowerWall

81 {

82 type wall;

83 faces

84 (

85 (0 1 13 12)

86 (1 5 17 13)

87 (5 6 18 17)

88 (2 14 18 6)

89 (2 3 15 14)

90 );

91 }

92 atmosphere

93 {

94 type patch;

95 faces

96 (

97 (8 20 21 9)

98 (9 21 22 10)

99 (10 22 23 11)

100 );

101 }

102);

103

104

105// ************************************************************************* //

2.3.2 Boundary conditions

The user can examine the boundary geometry generated by blockMesh by viewing the boundary file in the constant/polyMesh directory. The file contains a list of 5 boundary patches: leftWall, rightWall, lowerWall, atmosphere and defaultFaces.

The user should notice the type of the patches. Firstly, the atmosphere is a standard patch, i.e. has no special attributes, merely an entity on which boundary conditions can be specified. Then, the defaultFaces patch is formed of block faces that are omitted from the boundary sub-dictionary in the blockMeshDict file. Those block faces form a patch whose properties are specified in a defaultPatch sub-dictionary in in the blockMeshDict file. In this case, the default type is set to empty since the patch normal is in the direction we will not solve in this 2D case.

The leftWall,

rightWall and lowerWall patches are each a wall. Like the generic patch, the wall type contains no geometric or topological

information about the mesh and only differs from the plain

patch in that it identifies the

patch as a wall, should an application need to know, e.g. to apply special wall surface

modelling. For example, the interFoam solver includes modelling of

surface tension and can include wall adhesion at the contact point

between the interface and wall surface. Wall adhesion models can be

applied through a special boundary condition on the alpha ( ) field, e.g. the constantAlphaContactAngle boundary condition, which

requires the user to specify a static contact angle, theta0.

) field, e.g. the constantAlphaContactAngle boundary condition, which

requires the user to specify a static contact angle, theta0.

In this tutorial we would like to ignore surface

tension effects between the wall and interface. We can do this by

setting the static contact angle,  . However, rather than

using the constantAlphaContactAngle boundary

condition, the simpler zeroGradient can be applied to alpha on the walls.

. However, rather than

using the constantAlphaContactAngle boundary

condition, the simpler zeroGradient can be applied to alpha on the walls.

The top boundary is free to the atmosphere so needs to permit both outflow and inflow according to the internal flow. We therefore use a combination of boundary conditions for pressure and velocity that does this while maintaining stability. They are:

- prghTotalPressure, applied to the pressure

field, without the hydrostatic component,

, which is a

fixedValue condition calculated

from a specified total pressure p0 and local velocity U;

, which is a

fixedValue condition calculated

from a specified total pressure p0 and local velocity U; - pressureInletOutletVelocity, applied to

velocity

, which sets zeroGradient on all components of

, which sets zeroGradient on all components of

,

except where there is inflow, in which case a fixedValue condition is applied to the

tangential component;

,

except where there is inflow, in which case a fixedValue condition is applied to the

tangential component; - inletOutlet applied to other fields, which is a zeroGradient condition when flow outwards, fixedValue when flow is inwards.

At all wall boundaries, the fixedFluxPressure boundary condition is applied to the pressure field, which adjusts the pressure gradient so that the boundary flux matches the velocity boundary condition for solvers that include body forces such as gravity and surface tension.

The defaultFaces patch representing the front and back planes of the 2D problem, is, as usual, an empty type.

2.3.3 Phases

The fluid phases are specified in the phaseProperties file in the constant directory as follows:

17phases (water air);

18

19sigma 0.07;

20

21

22// ************************************************************************* //

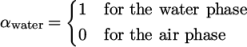

It lists two phases, water and air. Equations for phase fraction are

solved for the phases in the list, except the last phase listed, i.e. air in this case. Since there are only two

phases, only one phase fraction equation is solved in this case,

for the water phase fraction  , specified in the file

alpha.water in the

0 directory.

, specified in the file

alpha.water in the

0 directory.

The phaseProperties file also contains an entry

for the surface tension between the two phases, specified by the

keyword sigma in units  .

.

2.3.4 Setting initial fields

Unlike the previous cases, we shall now specify

a non-uniform initial condition for the phase fraction  where

where

|

(2.15) |

17defaultFieldValues

18(

19 volScalarFieldValue alpha.water 0

20);

21

22regions

23(

24 boxToCell

25 {

26 box (0 0 -1) (0.1461 0.292 1);

27 fieldValues

28 (

29 volScalarFieldValue alpha.water 1

30 );

31 }

32);

33

34

35// ************************************************************************* //

The defaultFieldValues sets the default value of

the fields, i.e. the value the

field takes unless specified otherwise in the regions sub-dictionary. That sub-dictionary contains a

list of subdictionaries containing fieldValues that override the defaults in a specified region.

The region creates a set of points, cells or faces based on some

topological constraint. Here, boxToCell creates a bounding box within a vector minimum and

maximum to define the set of cells of the water region. The phase

fraction  is defined as 1 in this region.

is defined as 1 in this region.

The setFields utility reads fields from file and, after re-calculating those fields, will write them back to file. In the damBreak tutorial, the alpha.water field is initially stored as a backup named alpha.water.orig. A field file with the .orig extension is read in when the actual file does not exist, so setFields will read alpha.water.orig but write the resulting output to alpha.water (or alpha.water.gz if compression is switched on). This way the original file is not overwritten, so can be reused.

The user should therefore execute setFields like any other utility by:

setFields

2.3.5 Fluid properties

The physical properties for the air and water

phases are specified in physicalProperties.air and physicalProperties.water files,

respectively, in the constant

directory. In each file, the viscosity model is selected by the

viscosityModel keyword. The constant model is selected for both fluids, i.e. representing them as Newtonian fluids

with a kinematic viscosity specified by the nu keyword in units  . Other non-Newtonian

viscosity models are described in section 7.3

. The density of each

fluid is specified by the keyword rho in units

. Other non-Newtonian

viscosity models are described in section 7.3

. The density of each

fluid is specified by the keyword rho in units  . The physicalProperties.air file is shown below

as an example:

. The physicalProperties.air file is shown below

as an example:

17viscosityModel constant;

18

19nu 1.48e-05;

20

21rho 1;

22

23

24// ************************************************************************* //

Gravitational acceleration is uniform across

the domain and is specified in a file named g in the constant directory. Unlike a normal field

file, e.g. U and p, g is a uniformDimensionedVectorField and so simply

contains a set of dimensions

and a value that represents

for

this tutorial:

for

this tutorial:

17dimensions [0 1 -2 0 0 0 0];

18value (0 -9.81 0);

19

20

21// ************************************************************************* //

2.3.6 Turbulence modelling

As in the cavity example, the choice of turbulence modelling method is selectable at run-time through the simulationType keyword in momentumTransport dictionary. In this example, we wish to run without turbulence modelling so we set laminar:

17simulationType laminar;

18

19

20// ************************************************************************* //

2.3.7 Time step control

Time step control is an important issue in

transient simulation and the surface-tracking algorithm in

interface-capturing solvers. The interFoam solver uses the multidimensional

universal limiter for explicit solution (MULES) method, created by

Henry Weller, to maintain boundedness of the phase fraction. The

Courant number  needs to be limited depending on the choice of

algorithm: with the explicit

MULES algorithm, an upper limit of

needs to be limited depending on the choice of

algorithm: with the explicit

MULES algorithm, an upper limit of  for stability is

typical in the region of the interface; but with semi-implicit MULES, specified by the

MULESCorr keyword in the fvSolution file, there is really no upper

limit in

for stability is

typical in the region of the interface; but with semi-implicit MULES, specified by the

MULESCorr keyword in the fvSolution file, there is really no upper

limit in  for stability, but instead the level is determined by

requirements of temporal accuracy.

for stability, but instead the level is determined by

requirements of temporal accuracy.

In general it is difficult to specify a fixed

time-step to satisfy the  criterion, so interFoam offers automatic adjustment of the

time step as standard in the controlDict. The user should specify

adjustTimeStep to be on and the the maximum

criterion, so interFoam offers automatic adjustment of the

time step as standard in the controlDict. The user should specify

adjustTimeStep to be on and the the maximum  for the phase fields,

maxAlphaCo, and other fields,

maxCo, to be 1.0. The upper limit

on time step maxDeltaT can be set to a value that

will not be exceeded in this simulation, e.g. 1.0.

for the phase fields,

maxAlphaCo, and other fields,

maxCo, to be 1.0. The upper limit

on time step maxDeltaT can be set to a value that

will not be exceeded in this simulation, e.g. 1.0.

By using automatic time step control, the steps themselves are never rounded to a convenient value. Consequently if we request that OpenFOAM saves results at a fixed number of time step intervals, the times at which results are saved are somewhat arbitrary. However even with automatic time step adjustment, OpenFOAM allows the user to specify that results are written at fixed times; in this case OpenFOAM forces the automatic time stepping procedure to adjust time steps so that it ‘hits’ on the exact times specified for write output. The user selects this with the adjustableRunTime option for writeControl in the controlDict dictionary. The controlDict dictionary entries should be:

17application interFoam;

18

19startFrom startTime;

20

21startTime 0;

22

23stopAt endTime;

24

25endTime 1;

26

27deltaT 0.001;

28

29writeControl adjustableRunTime;

30

31writeInterval 0.05;

32

33purgeWrite 0;

34

35writeFormat binary;

36

37writePrecision 6;

38

39writeCompression off;

40

41timeFormat general;

42

43timePrecision 6;

44

45runTimeModifiable yes;

46

47adjustTimeStep yes;

48

49maxCo 1;

50maxAlphaCo 1;

51

52maxDeltaT 1;

53

54

55// ************************************************************************* //

2.3.8 Discretisation schemes

The MULES method, used by the interFoam solver, maintains boundedness of the phase fraction independently of the underlying numerical scheme, mesh structure, etc. The choice of schemes for convection are therfore not restricted to those that are strongly stable or bounded, e.g. upwind differencing.

The convection schemes settings are made in the

divSchemes sub-dictionary of

the fvSchemes dictionary. In this example,

the convection term in the momentum equation ( ), denoted by the

div(rhoPhi,U) keyword, uses

Gauss linearUpwind grad(U) to produce good

accuracy. Here, we have opted for best stability with

), denoted by the

div(rhoPhi,U) keyword, uses

Gauss linearUpwind grad(U) to produce good

accuracy. Here, we have opted for best stability with  . The

. The

term, represented by the div(phi,alpha) keyword uses a bespoke

interfaceCompression scheme

where the specified coefficient is a factor that controls the

compression of the interface where: 0 corresponds to no

compression; 1 corresponds to conservative compression; and,

anything larger than 1, relates to enhanced compression of the

interface. We generally adopt a value of 1.0 which is employed in

this example.

term, represented by the div(phi,alpha) keyword uses a bespoke

interfaceCompression scheme

where the specified coefficient is a factor that controls the

compression of the interface where: 0 corresponds to no

compression; 1 corresponds to conservative compression; and,

anything larger than 1, relates to enhanced compression of the

interface. We generally adopt a value of 1.0 which is employed in

this example.

The other discretised terms use commonly employed schemes so that the fvSchemes dictionary entries should therefore be:

17ddtSchemes

18{

19 default Euler;

20}

21

22gradSchemes

23{

24 default Gauss linear;

25}

26

27divSchemes

28{

29 div(rhoPhi,U) Gauss linearUpwind grad(U);

30 div(phi,alpha) Gauss interfaceCompression vanLeer 1;

31 div(((rho*nuEff)*dev2(T(grad(U))))) Gauss linear;

32}

33

34laplacianSchemes

35{

36 default Gauss linear corrected;

37}

38

39interpolationSchemes

40{

41 default linear;

42}

43

44snGradSchemes

45{

46 default corrected;

47}

48

49

50// ************************************************************************* //

2.3.9 Linear-solver control

In the fvSolution file, the alpha.water sub-dictionary in solvers contains elements that are specific to interFoam. Of particular interest is the nAlphaCorr keyword which controls the number of iterations of the phase fraction equation within a solution step. The iteration is used to overcome nonlinearities in the advection which are present in this case due to the interfaceCompression scheme.

2.3.10 Running the code

Running of the code has been described in detail in previous tutorials. Try the following, that uses tee, a command that enables output to be written to both standard output and files:

cd $FOAM_RUN/damBreak

interFoam | tee log

2.3.11 Post-processing

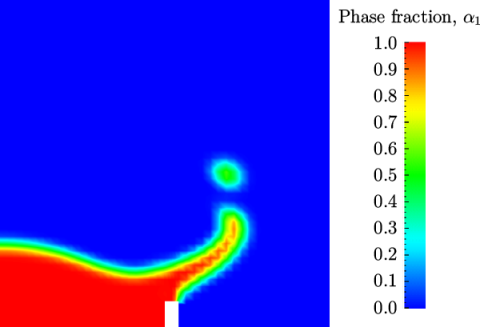

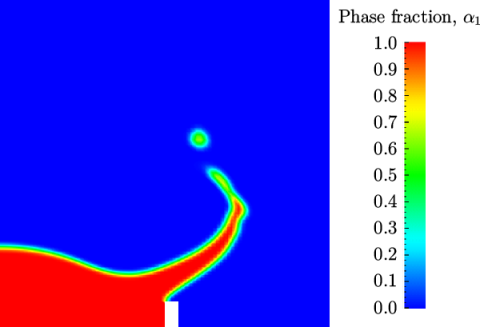

Post-processing of the results can now be done in the usual way. The user can monitor the development of the phase fraction alpha.water in time, e.g. see Figure 2.23 .

2.3.12 Running in parallel

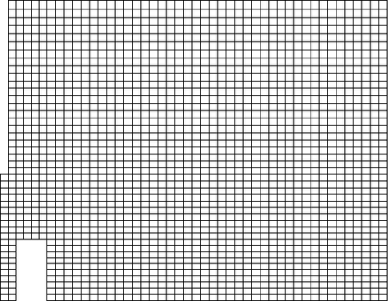

The results from the previous example are generated using a fairly coarse mesh. We now wish to increase the mesh resolution and re-run the case. The new case will typically take a few hours to run with a single processor so, should the user have access to multiple processors, we can demonstrate the parallel processing capability of OpenFOAM.

The user should first clone the damBreak case, e.g. by

run

foamCloneCase damBreak damBreakFine

blocks

(

hex (0 1 5 4 12 13 17 16) (46 10 1) simpleGrading (1 1 1)

hex (2 3 7 6 14 15 19 18) (40 10 1) simpleGrading (1 1 1)

hex (4 5 9 8 16 17 21 20) (46 76 1) simpleGrading (1 2 1)

hex (5 6 10 9 17 18 22 21) (4 76 1) simpleGrading (1 2 1)

hex (6 7 11 10 18 19 23 22) (40 76 1) simpleGrading (1 2 1)

);

As the mesh has now changed from the damBreak example, the user must

re-initialise the phase field alpha.water in the 0 time directory since it contains a

number of elements that is inconsistent with the new mesh. Note

that there is no need to change the U and p_rgh

fields since they are specified as uniform which is independent of the number

of elements in the field. We wish to initialise the field with a

sharp interface, i.e. it

elements would have  or

or  . Updating the field with mapFields may produce interpolated values

. Updating the field with mapFields may produce interpolated values

at

the interface, so it is better to rerun the setFields utility.

at

the interface, so it is better to rerun the setFields utility.

The mesh size is now inconsistent with the number of elements in the alpha.water file in the 0 directory, so the user must delete that file so that the original alpha.water.orig file is used instead.

rm 0/alpha.water

setFields

The method of parallel computing used by OpenFOAM is known as domain decomposition, in which the geometry and associated fields are broken into pieces and allocated to separate processors for solution. The first step required to run a parallel case is therefore to decompose the domain using the decomposePar utility. There is a dictionary associated with decomposePar named decomposeParDict which is located in the system directory of the tutorial case. Also, sample dictionaries can be found within the etc directory in the OpenFOAM installation, which can be copied to the case directory by running the foamGet script, e.g. (you do not need to do this):

foamGet decomposeParDict

The first entry is numberOfSubdomains which specifies the number of subdomains into which the case will be decomposed, usually corresponding to the number of processors available for the case.

In this tutorial, the method of decomposition should be

simple and the corresponding

simpleCoeffs should be edited

according to the following criteria. The domain is split into

pieces, or subdomains, in the  ,

,  and

and  directions, the

number of subdomains in each direction being given by the vector

directions, the

number of subdomains in each direction being given by the vector

. As

this geometry is 2 dimensional, the 3rd direction,

. As

this geometry is 2 dimensional, the 3rd direction,  , cannot be split,

hence

, cannot be split,

hence  must equal 1. The

must equal 1. The  and

and  components of

components of  split the domain in the

split the domain in the

and

and

directions and must be specified so that the number of subdomains

specified by

directions and must be specified so that the number of subdomains

specified by  and

and  equals the specified numberOfSubdomains, i.e.

equals the specified numberOfSubdomains, i.e.  numberOfSubdomains. It is beneficial to keep

the number of cell faces adjoining the subdomains to a minimum so,

for a square geometry, it is best to keep the split between the

numberOfSubdomains. It is beneficial to keep

the number of cell faces adjoining the subdomains to a minimum so,

for a square geometry, it is best to keep the split between the

and

and

directions should be fairly even.

directions should be fairly even.

For example, let us assume we wish to run on 4

processors. We would set numberOfSubdomains to 4 and  . The user should

run decomposePar with:

. The user should

run decomposePar with:

decomposePar

The user should consult section 3.4 for details of how to run a case in parallel; in this tutorial we merely present an example of running in parallel. We use the openMPI implementation of the standard message-passing interface (MPI). As a test here, the user can run in parallel on a single node, the local host only, by typing:

mpirun -np 4 interFoam -parallel > log &

The user may run on more nodes over a network by creating a file that lists the host names of the machines on which the case is to be run as described in section 3.4.3 . The case should run in the background and the user can follow its progress by monitoring the log file as usual.

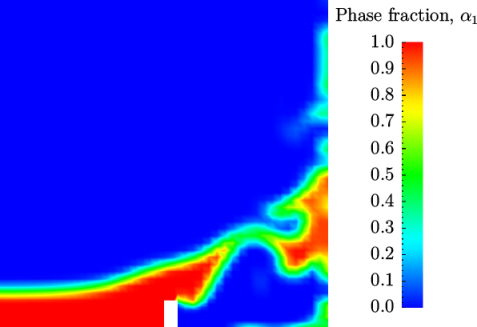

2.3.13 Post-processing a case run in parallel

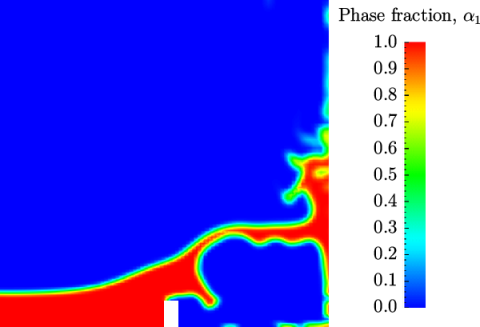

Once the case has completed running, the decomposed fields and mesh can be reassembled for post-processing using the reconstructPar utility. Simply execute it from the command line. The results from the fine mesh are shown in Figure 2.25 . The user can see that the resolution of interface has improved significantly compared to the coarse mesh.

The user may also post-process an individual region of the decomposed domain individually by simply treating the individual processor directory as a case in its own right. For example if the user starts paraFoam by

paraFoam -case processor1

.

.

with refined

mesh.

with refined

mesh.