6.1 Reynolds experiment

Reynolds distinguished the laminar and

turbulent flow regimes in his influential experiments in the early

1880s.1 At

that time, Poisueille’s law predicted correctly that the resistance

to flow in a pipe  for laminar flow at speed

for laminar flow at speed  , which typically

occurs at small

, which typically

occurs at small  and/or diameter

and/or diameter  . Reynolds wanted to

understand why, at higher

. Reynolds wanted to

understand why, at higher  and/or

and/or  , resistance

, resistance

(approximately).

(approximately).

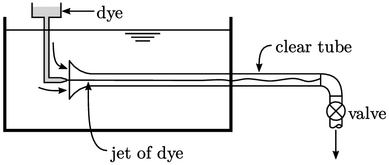

His experiment used a large, glass-walled tank

filled with water. A glass tube with a flared intake passed through

the tank and out through one wall. Water from the tank flowed along

the tube at speed  , controlled by an outlet valve. A jet of liquid

dye was injected at the inlet to the tube to visualise the flow.

, controlled by an outlet valve. A jet of liquid

dye was injected at the inlet to the tube to visualise the flow.

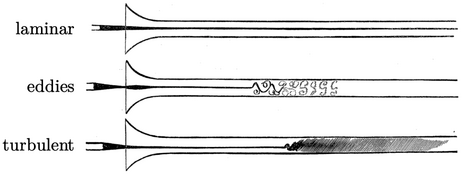

The observed behaviour is shown in Reynolds’s

original drawings on the following page. At sufficiently low speed,

the streak of dye followed a straight line along the tube,

indicating laminar flow. The speed was increased in small steps

until at some distance from the tube intake (typically,

30 )

the dye would mix with the water, rapidly filling the tube. This

marked the transition to turbulent

flow.

)

the dye would mix with the water, rapidly filling the tube. This

marked the transition to turbulent

flow.

Reynolds made the following important observations.

- Distinct eddies were visible during turbulent flow, see above.

- The transition speed was very sensitive to disturbances in the water entering the tube, even due to the temperature variations in the water.

- Before full transition was reached, intermittent “spots” of turbulence appeared and disappeared.

Reynolds number

Reynolds argued that the transition is

controlled by the Reynolds number,  from

Eq. (2.68

), using the

characteristic length

from

Eq. (2.68

), using the

characteristic length  in a pipe. His deduction was based on the idea

of scale similarity, introduced in Sec. 2.21

.

in a pipe. His deduction was based on the idea

of scale similarity, introduced in Sec. 2.21

.

He observed that with minimal disturbance in the

tank, the transition to turbulent flow occurred at  13000. When

disturbances were evidently present, the transition occurred at

13000. When

disturbances were evidently present, the transition occurred at

2000. An updated view for pipe flow is that for

2000. An updated view for pipe flow is that for

2000, all disturbances will decay preventing the onset

of turbulent flow. For

2000, all disturbances will decay preventing the onset

of turbulent flow. For  2000, transition depends on initial

disturbances and the roughness of the pipe wall.

2000, transition depends on initial

disturbances and the roughness of the pipe wall.